Transforming a Warehouse into a State-of-the-Art Food Factory

Overview & Objectives

Project Parrot was a large-scale industrial transformation project undertaken by Ambrey Baker Construction, repurposing an aging warehouse into a modern, high-tech food production facility. The project involved extensive structural modifications, including a new reinforced roof, a front extension for loading bays, and a rear extension for plant and refrigeration to support upgraded infrastructure.

The client, a leading food manufacturer, sought to expand operations by transforming an outdated warehouse into a cutting-edge facility that met BRCGS and HACCP food safety standards. The key objectives included:

1 Optimizing the structure to accommodate food production equipment while ensuring compliance with industry regulations.

2 Upgrading hygiene and safety measures to meet strict food industry requirements.

3 Improving operational efficiency with dedicated areas for loading, plant, and refrigeration.

Through innovative engineering, careful planning, and seamless execution, Ambrey Baker successfully delivered a high-efficiency food manufacturing plant, setting new benchmarks for industrial refurbishment in the food sector.

Scope of Work

Reroofing & Structural Upgrades

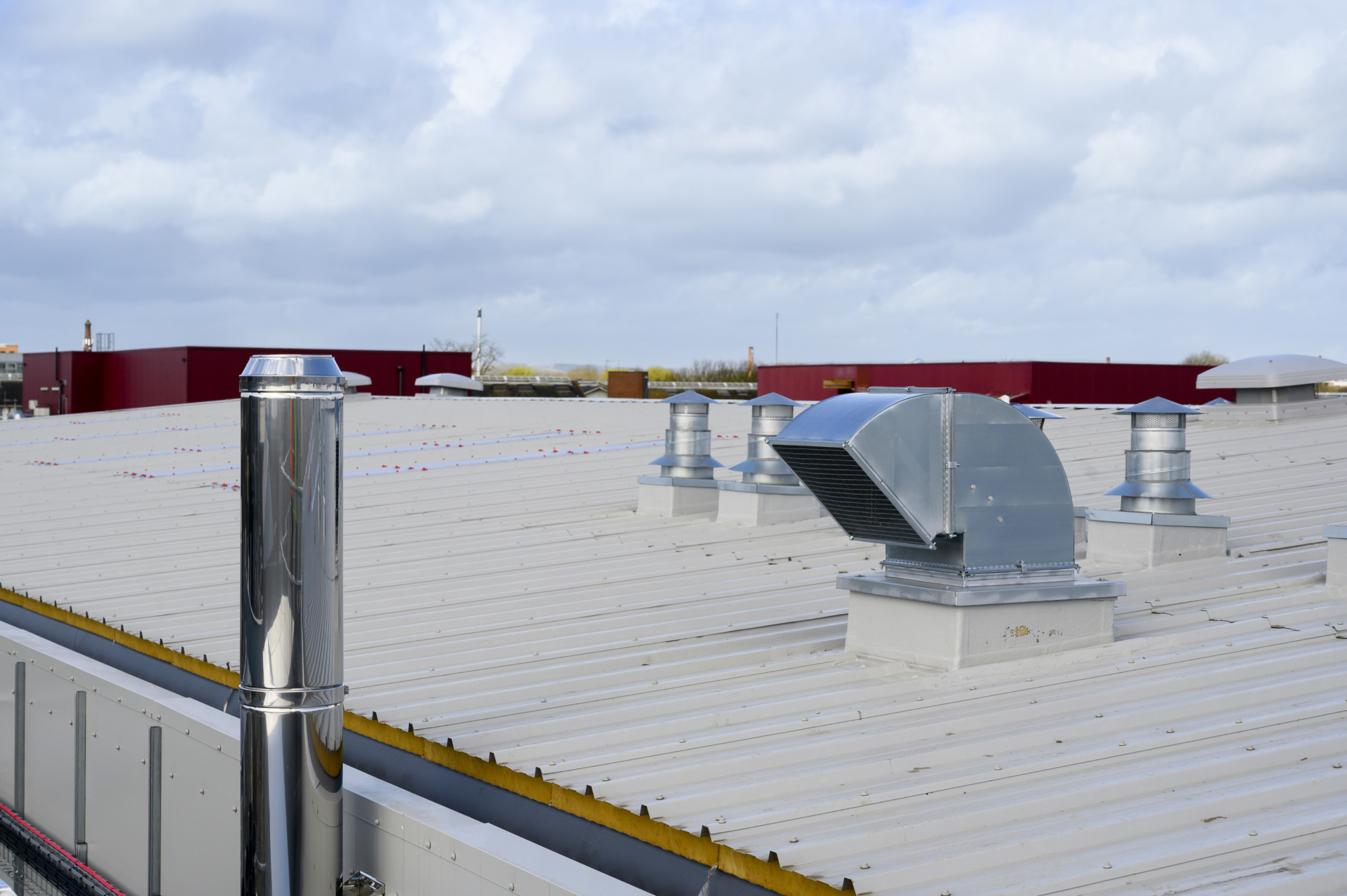

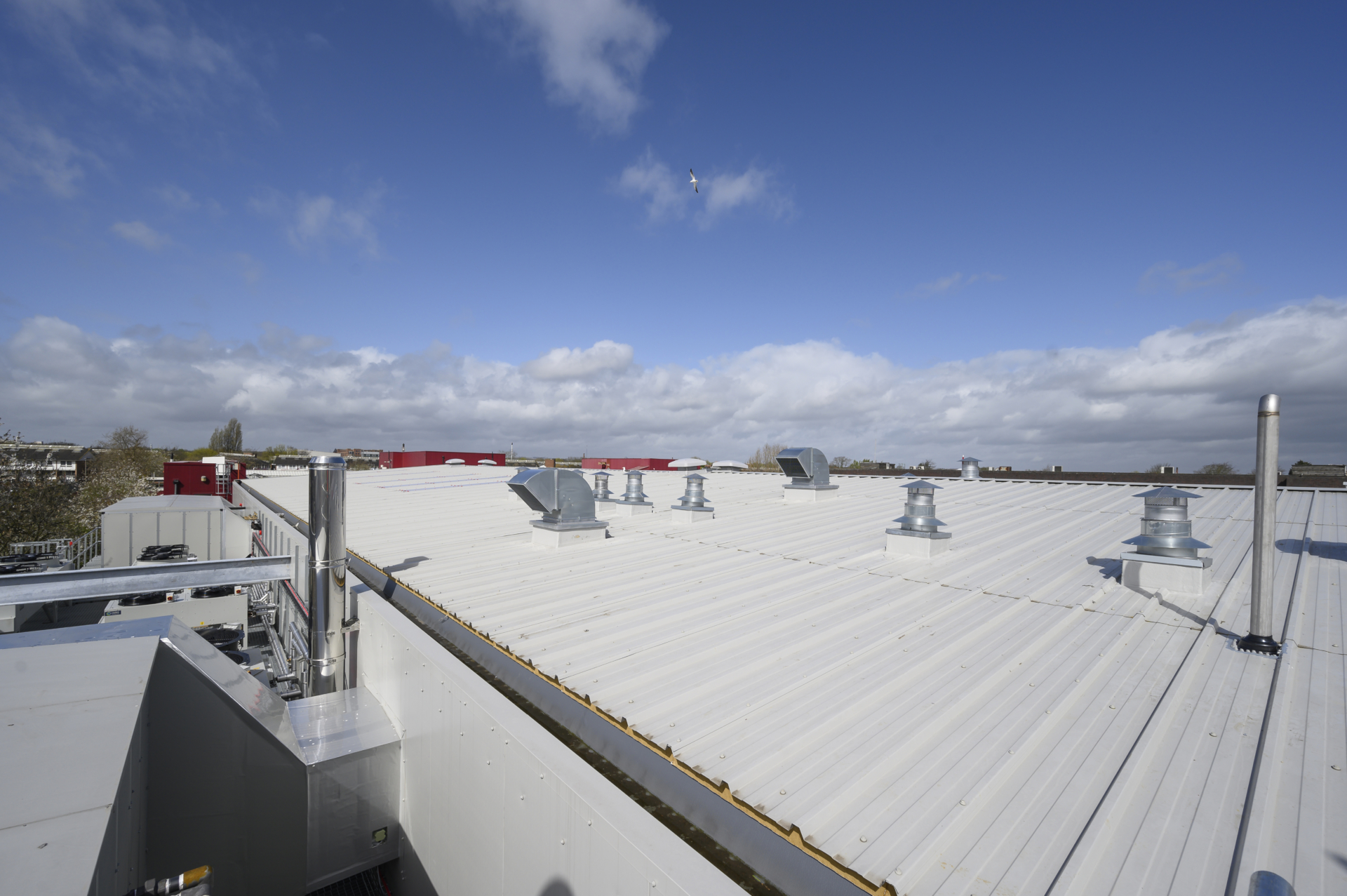

- Complete removal and replacement of the existing roof with a reinforced system to support plant installations and enhance insulation.

- Upgraded roof drainage systems to prevent water pooling and improve weather resistance.

Extensions & Steelwork

- New front extension to accommodate dedicated loading bays, optimizing logistics for incoming raw materials and outgoing finished products.

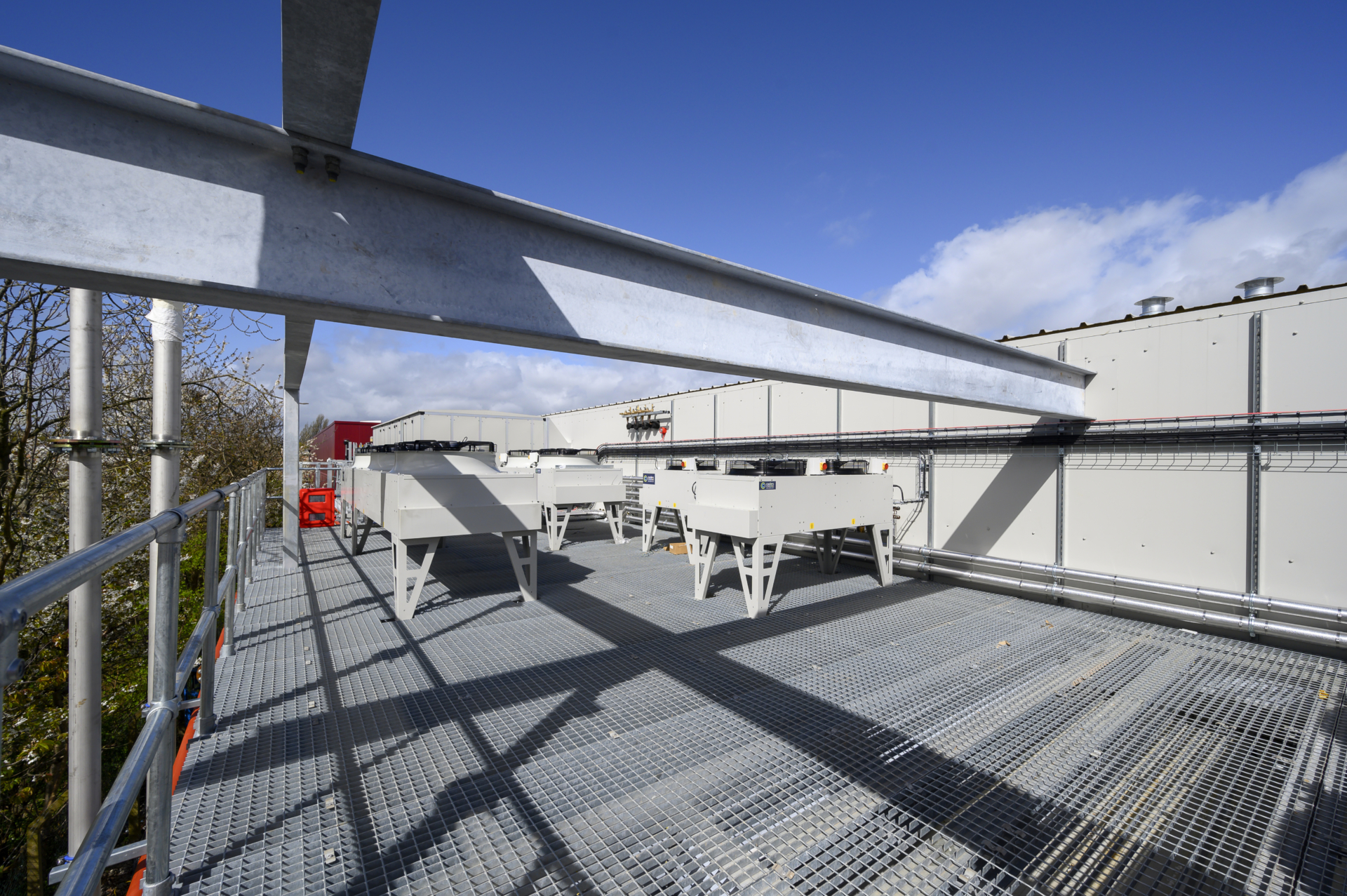

- New rear extension for plant housing and refrigeration units, ensuring temperature control and efficient equipment placement.

- Primary and secondary steelwork, including reinforced structural supports and mezzanine installation for optimized space utilization.

Groundworks & Drainage

- Excavation and foundation work for new extensions.

- Installation of new underground drainage systems to support waste management and prevent contamination risks.

- External concrete yard works for HGV access and maneuvering.

Internal Fit-Out & Food-Safe Finishes

- Hygienic internal envelope including food-safe wall and ceiling panels for easy maintenance.

- Antimicrobial flooring for hygiene compliance.

- Partitioning and segregation of processing zones to minimize contamination risks.

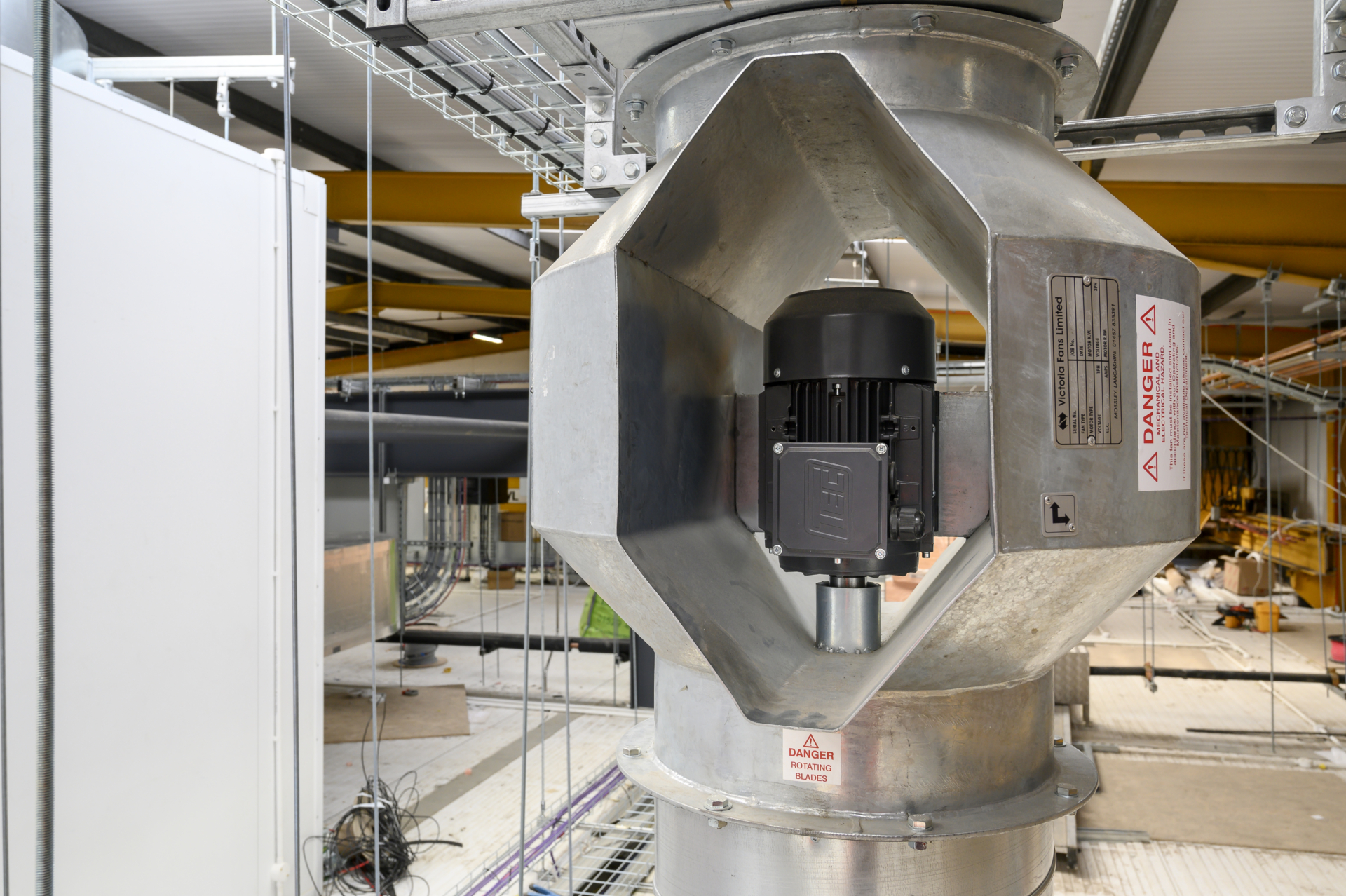

Mechanical & Electrical (M&E) Installations

- Full electrical distribution system to support food production equipment.

- Installation of HVAC systems, ensuring controlled air quality and temperature regulation.

- Refrigeration and cooling systems integrated within the plant extension.

- Smart monitoring systems for real-time oversight of production conditions.

Energy Efficiency & Sustainability Measures

- LED lighting throughout the facility for reduced energy consumption.

- Upgraded insulation to improve thermal efficiency and reduce operational costs.

- Water-efficient fixtures to minimize waste and enhance sustainability.

- Heat recovery systems to repurpose excess heat from production processes.

Challenges & Solutions

Adapting an Outdated Structure for Food Production:

Solution: Ambrey Baker reinforced the structural steelwork, installed a new mezzanine, and optimized the layout to improve production flow and efficiency.

Ensuring Hygiene & Food Safety Compliance

The team has decades of experience in installing food-safe internal panels, antimicrobial flooring, and a new drainage system to minimize contamination risks and ensure easy maintenance.

Upgrading M&E Infrastructure for Modern Production

New electrical distribution systems, high-efficiency HVAC, and refrigeration units were installed to maintain precise climate control and power efficiency.

Related Case Studies

Overview & Objectives Ambrey Baker was appointed as principal contractor for a full strip-out and rebuild of an existing processing space at Holme Farm. The...

Project Background Different Dog is an innovative pet food company based in Telford, focused on delivering freshly cooked, all natural pet food. With rapid growth...

Different Dog is an innovative pet food company based in Telford, focused on delivering freshly cooked, all natural pet food. With rapid growth from a...