Reinventing Frozen: The Technical Edge in Food Manufacturing’s Quiet Revolution

In the world of food manufacturing, where innovation is often associated with freshness, flavour, and formulation, it might come as a surprise that one of the most dynamic spaces in 2025 is tucked away behind a glass door in the supermarket. The frozen food aisle, long viewed as the domain of low-cost, low-quality convenience, has undergone a dramatic reinvention—quietly becoming a focal point for premiumisation, technical innovation, and consumer relevance. For technical teams working at large food manufacturers, the message is clear: now is the time to start looking seriously at what’s happening in frozen.

Over the past decade, the UK frozen food market has shifted from stagnation to strength, growing from around £5.5 billion in 2015 to £8.5 billion by 2024, with forecasts suggesting it could exceed £12 billion by the early 2030s. This isn’t just a case of inflation or temporary demand spikes; it’s a fundamental rethinking of what frozen can deliver. At the heart of this transformation is consumer behaviour. Shoppers no longer see frozen food as a compromise. Increasingly, it’s seen as a smart, sustainable, and – crucially – high-quality choice. They’re trading up for premium ready meals, gourmet frozen sides, plant-based innovations, and flash-frozen world cuisine. And they’re doing it not because it’s cheaper, but because the experience is better.

This shift is particularly significant for technical teams because it redefines the scope of frozen food development. Gone are the days of basic trays of lasagna and generic mixed veg. Today, frozen is a platform for serious culinary and technical creativity. Consider COOK, whose frozen meals are handmade using techniques usually reserved for restaurants. Or M&S, where frozen patisserie, seafood, and plant-based lines are now central to their food innovation strategy. Consumers are expecting more from frozen, and it’s falling on product developers, process engineers, and QA teams to meet that expectation without sacrificing operational efficiency.

One of the most immediate challenges is delivering culinary quality at scale. Textures must survive freezing and reheating without compromise; sauces must remain stable under temperature stress; premium flourishes like sourdough crusts or layered desserts must hold their structure through distribution and shelf life. Technical teams are responding with advances in cryogenic and impingement freezing, more sophisticated starch and fat systems, and better predictive modelling for freeze-thaw cycles. This is where the real innovation is happening—not on the plate, but in the plant.

Health and sustainability are two other pillars transforming the frozen category. As reformulation pressures increase across all food formats, frozen presents a unique opportunity: products that are naturally preservative-free, portion-controlled, and waste-reducing. Technical teams are reformulating recipes to meet HFSS guidelines while still delivering flavour and visual appeal after reheating. Meanwhile, sustainability-minded manufacturers are exploring recyclable packaging formats and optimising energy usage in cold chain logistics. Flash-freezing allows manufacturers to work with seasonal produce, reduce raw material waste, and provide year-round consistency—an advantage that chilled formats struggle to match.

Plant-based frozen food is another fast-growing segment. It combines three things consumers now demand: health, sustainability, and convenience. The technical complexities of plant-based proteins are already well documented—binding systems, emulsification, fat dispersion—but freezing these systems brings new variables into play. It’s not just about getting the burger to hold together during cooking, but ensuring it reheats well from frozen, has the right bite, and fits clean-label criteria. Add to that consumer preferences for global flavours and functional benefits (like protein boosts or fibre content), and the frozen aisle becomes a testing ground for high-impact innovation.

The resurgence of frozen isn’t limited to the product itself—it’s visible in how it’s sold and perceived. Retailers are investing in freezer upgrades, glass-door merchandising, and dedicated frozen sections that showcase products as aspirational rather than utilitarian. Some are creating chef-led collaborations and limited-edition lines. Others are leaning into click-and-collect and D2C channels, which often rely heavily on frozen formats for logistics and shelf life reasons. Packaging and presentation, therefore, become technical considerations: materials need to perform in freezing and reheating environments, be visually appealing in a retail context, and align with sustainability goals.

From a supply chain perspective, frozen offers resilience and control. In times of economic uncertainty, labour shortages, and ingredient volatility, having a product format that can be made in bulk, stored, and distributed flexibly is a strategic advantage. Cold chain logistics, while energy-intensive, are improving, and advances in monitoring and energy-efficient storage are making frozen more scalable. For large manufacturers, especially those dealing with tight margins or variable commodity costs, frozen offers the ability to decouple production from distribution and manage costs more effectively.

The real story here is not just that frozen food is growing. It’s that frozen food is becoming an engine of innovation across every function of a manufacturing business—from R&D and new product development, to packaging, logistics, and sustainability. For technical teams, this means new briefs, new processes, and new ways of collaborating. It means looking at frozen not as an afterthought, but as a platform for progress.

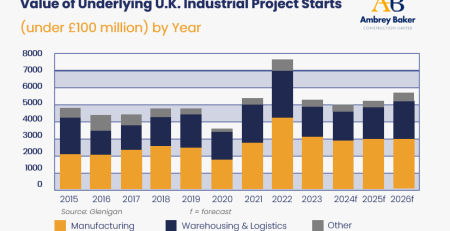

As manufacturers respond to the frozen food renaissance with new products, technologies, and formats, many are also confronting the physical and operational limitations of their existing facilities. That’s where a partner like Ambrey Baker Industrial Solutions can make a critical difference. With nearly 40 years of experience in the food sector, Ambrey Baker offers integrated support across feasibility, design, planning, and the construction or alteration of complex food manufacturing environments. Whether you’re expanding freezer capacity, reconfiguring process lines for frozen formats, or future-proofing your facility to handle mixed-mode production (chilled, ambient, and frozen), Ambrey Baker’s specialist knowledge in hard FM and capital project delivery helps technical teams bring innovation to life—safely, efficiently, and with minimal disruption. In an industry where agility, hygiene, and energy efficiency are non-negotiable, they bring the infrastructure expertise to match the pace of product innovation.

For further information or enquiries regarding project coordination, refurbishment and maintenance delivery, lifecycle planning, and support within live operational environments, please contact:

Matthew Waldeck – Head of Client Solutions