Concept to Completion: Purpose Built Manufacturing Facility

Overview & Objectives

Fen-Bay Services Ltd, a specialist in industrial doors, dock levellers, and loading bay equipment, required a purpose-built facility to support continued expansion. Ambrey Baker was appointed to deliver a modern steel-framed office and warehouse building on a brownfield site in Spalding, providing integrated space for operations, customer service, and administration.

Scope of Work

Steel Frame & Structural Envelope

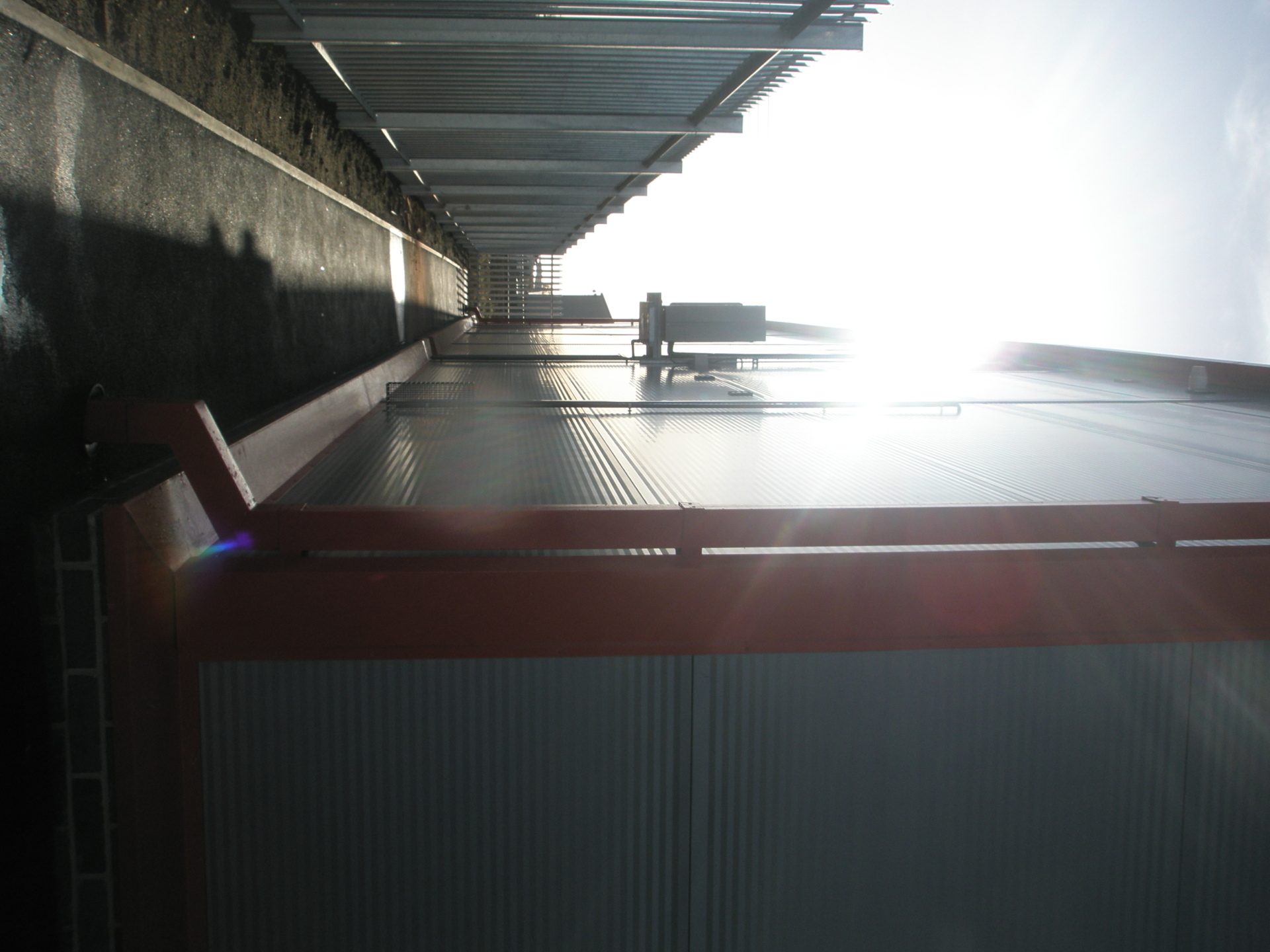

Design and construction of a steel portal frame building, purpose-built to house a combined warehouse and two-storey office block.

Installation of insulated composite cladding to external walls and roof for energy efficiency and low maintenance.Groundworks & Drainage

Site clearance and excavation of a previously developed brownfield plot.

Installation of reinforced concrete foundations and structural pads to support steel column loads.

Formation of underground drainage and ducting systems, with connection to existing services.Internal Fit-Out – Office & Welfare Facilities

Partitioning of ground and first-floor spaces to create private offices, a boardroom, open-plan workspaces, kitchenettes, and WC facilities.

Suspended ceilings with recessed LED lighting throughout office zones.

Carpet-tile flooring and hygienic vinyl in welfare areas for durability and ease of maintenance.

Wall-mounted dado trunking with data and power points to support IT infrastructure.Warehouse Fit-Out

Open-plan industrial space with power-floated concrete floor slab.

Installation of high-level lighting, emergency lighting, and provision for future racking layout.

Service penetrations, fire exit provisions, and dock leveller pit incorporated as part of the warehouse design.Mechanical & Electrical (M&E) Installations

Full electrical installation including distribution boards, lighting, fire alarms, emergency lighting, and external luminaires.

Mechanical systems including wall-mounted electric heating panels and air conditioning units for key office zones.

Kitchenettes fitted with sinks, water heaters, and base/wall units to suit staff use.External Works & Parking

Tarmac surfacing to form staff and visitor car park with marked bays and accessible spaces.

Concrete yard slab to provide HGV access to the warehouse loading bay.

Perimeter fencing and secure entrance gates integrated to match the industrial estate setting.

Challenges & Solutions

Live industrial estate with restricted crane access

Solution: Detailed lift plans and logistics coordination enabled safe and efficient steel erection using mobile cranes and access platforms.

Ground stability for steel columns

Solution: Engineered foundation pads with reinforced bases and custom bolt sets ensured a structurally sound and accurate frame alignment.

Programme certainty during mixed weather conditions

Solution: Sub-base and drainage were prioritised early, maintaining momentum through wet spells and enabling envelope works to proceed without delay.

Related Case Studies

Overview & Objectives Ambrey Baker was appointed as principal contractor for a full strip-out and rebuild of an existing processing space at Holme Farm. The...

Overview & Objectives Project Parrot was a large-scale industrial transformation project undertaken by Ambrey Baker Construction, repurposing an aging warehouse into a modern, high-tech food...

Project Background Different Dog is an innovative pet food company based in Telford, focused on delivering freshly cooked, all natural pet food. With rapid growth...