The Strategy Saving Millions in UK Food production: Master Planning for Factory Optimisation

In British food and industrial manufacturing, real estate is not just bricks and mortar: it is one of the most strategic levers a business controls. Yet too often, sites evolve organically, shaped by short-term fixes and reactive investment. The result is a patchwork of production spaces, warehouses, loading bays, and welfare facilities that rarely operate as a single coherent system. Master planning – the discipline of shaping a factory footprint around long-term strategic goals – is now emerging as one of the most important tools to keep operators competitive in an era of tight margins, regulatory scrutiny, and shifting consumer demand.

Industry voices underline the urgency. The Food and Drink Federation (FDF) has reported that UK food manufacturers invested over £4.5 billion in 2023 on plant and equipment, with a significant proportion aimed at automation and efficiency. Yet automation is only as effective as the space in which it is deployed. A robotised packing line, for instance, loses its advantage if material flows are compromised by poor factory layouts. Here lies the case for master planning: transforming physical space into an active engine for productivity, compliance, and resilience.

Beyond the Drawing Board: Strategic Foundations

It is easy to mistake master planning for a design exercise. In reality, it is a strategic discipline, one that links production capacity, logistics, workforce movement, and even energy use into a single long-term vision. The Health and Safety Executive has repeatedly highlighted how inefficient layouts create not just bottlenecks but also real safety risks. Traffic clashes between forklifts and pedestrians, poorly zoned waste routes, and cramped welfare spaces are more than inefficiencies; they are liabilities.

By contrast, a master-planned facility is designed around clear flows of raw materials, packaging, people, and products. The golden rule – that paths should never unnecessarily cross – remains as relevant as ever. For food operators under BRCGS Issue 9 or customer-specific standards like Tesco’s TFMS, this is not just about efficiency but about audit readiness and risk control.

Compliance Woven into the Blueprint

The Food Standards Agency notes that factories must be designed to facilitate cleaning, maintenance, and hygiene controls. This is where master planning moves beyond machines and lines. It considers zoning for allergens, placement of welfare facilities, space for segregation of waste streams, and even the integration of maintenance corridors that allow engineers to work without disrupting production. As sustainability targets tighten, it also considers utility corridors, renewable integration, and insulation upgrades from the outset rather than as retrofits.

Flexibility: Designing for Unknown Futures

One of the most valuable outputs of a master plan is not today’s efficiency, but tomorrow’s adaptability. The past five years have shown how unpredictable food markets can be. Brexit reshaped export routes, COVID-19 rewrote workforce models, and now energy volatility is forcing businesses to rethink resilience. A facility built without flexibility becomes obsolete far faster than its depreciation cycle.

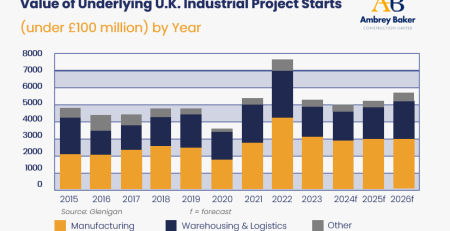

The FDF has flagged that labour shortages are accelerating investment in robotics, while a Make UK survey suggests that 48 per cent of manufacturers plan to increase automation spending by 2026. Master plans that anticipate this reality – with modular mezzanines, scalable storage, and adaptable utility networks – reduce the risk of expensive reconstruction later.

A Tool for Consolidation and Growth

Mergers and acquisitions are another force reshaping the sector. In the last two years, deals such as Pilgrim’s Pride’s acquisition of Randall Parker Foods and the continued consolidation in bakery and ready-meal sectors have underscored the pace of change. Each acquisition often brings overlapping assets. Without a plan, duplication drives inefficiency. With one, operators can consolidate footprints, rationalise sites, and cut overheads. The UK Government’s Construction Playbook stresses early planning to align infrastructure with business objectives, a principle increasingly recognised in food manufacturing where site consolidation strategies often unlock millions in long-term savings.

Embedding Net Zero into the Factory Fabric

Sustainability is no longer a bolt-on. The UK’s Net Zero Strategy identifies industrial sites as critical to achieving carbon reduction targets, with the food sector singled out as one of the largest industrial energy consumers. Master planning offers a unique opportunity to integrate low-carbon design – from energy-efficient refrigeration to smart logistics bays, solar canopies, and closed-loop water treatment – at the point of conception. This is not only environmentally sound but commercially essential, given soaring energy costs and growing retailer scrutiny of Scope 3 emissions.

Looking Ahead: Every Square Metre as a Strategic Asset

The long-term benefits of master planning ripple across the business: reduced operating costs, improved productivity, embedded compliance, enhanced safety, and future-proof flexibility. More than that, it transforms the way leadership teams view their estates. Land is no longer a static liability but a dynamic tool for competitiveness. In an industry where margins are measured in single digits and every square metre carries a cost, the question is simple: does every square metre also generate a return?

Foresight is the heart of master planning. It requires seeing a site not just as it is today but as it must perform in five, ten, or twenty years’ time. Those who embrace it can create facilities that are resilient, efficient, and sustainable. Those who do not risk being left with costly, outdated assets that drain value rather than drive it.

For further information or enquiries regarding project coordination, refurbishment and maintenance delivery, lifecycle planning, and support within live operational environments, please contact:

Matthew Waldeck – Head of Client Solutions