Heals Eggs – New Cooking Facility

Challenge

Heals Eggs Limited, a prominent player in the food industry, sought to establish a cutting-edge Egg Breaking and Pasteurising facility by converting an existing grain store into a Low care and High Care food production facility in Shrewsbury. Ambrey Baker was entrusted with key responsibilities in the construction process, focusing primarily on Underfloor Drainage, Stainless Steel Drainage Channels and Gullies, Stainless Steel Kerbing Polymer Build up screeds and Heavy duty Polyurethane Resin Floor finishes for both low care and high care egg pasteurising and moving on to white walling, panelling in collaboration with our trusted partners at A B C Floors Limited.

Solution

Drainage

A B C Floors Limited completed the Design and installation phases of drainage, cutting out the existing concrete slab, dedicated Low Care and High Care Drainage runs and the installation of Low care and High care Drainage channels and gullies.

Stainless Steel Kerbing

A B C Floors Limited designed and installed a selection of Stainless Steel Kerbs within the confines of the existing building. A selection of single sided, Double sided and clip on fully welded 304 Stainless Steel kerbs with integral coved junction at the correct height for the new floors.

Resin Flooring

A B C Floors Limited unrivalled knowledge of the food industry allowed them to meticulously design the correct flooring solutions to meet the specific needs of both Low Care and High Care finishes of the new facility, ensuring durability, easy maintenance, and compliance with industry regulations.

The Design and installation of the New Resin flooring is the most critical component for maintaining hygiene standards in food processing areas. The floor finishes comprise of Polymer screeds laid to falls and cross falls creating minimum falls of 1:00 to the new drainage system and a mix of 6mm and 9mm Resdev Unipack Pumadur HF Heavy duty Polyurethane screeds with all the relevant jointing details at drains kerbs perimeters.

White Walling and Panelling

Ambrey Baker’s expertise in construction and hygienic environments came to the fore during the white walling and panelling phase. Our team meticulously planned and executed the installation, ensuring a seamless and hygienic environment for Heals Eggs Limited New Egg Breaking and Pasteurising facility. The choice of materials and construction techniques prioritized cleanliness and compliance with industry standards.

Ambrey Baker remains dedicated to delivering tailored solutions for clients in the food and beverage sector, contributing to the success and growth of their businesses.

Outcome

The successful collaboration between Heals Eggs Limited, Ambrey Baker, and A B C Floors Limited resulted in the establishment of a state-of-the-art cooking facility in Shrewsbury. The white walling, panelling, and high-care floor installation contributed to creating a hygienic, efficient, and compliant environment for food processing. The facility now stands as a testament to Heals Eggs Limited commitment to quality and innovation in the food industry.

Ambrey Baker remains dedicated to delivering tailored solutions for clients in the food and beverage sector, contributing to the success and growth of their businesses.

Related Case Studies

Overview & Objectives Project Parrot was a large-scale industrial transformation project undertaken by Ambrey Baker Construction, repurposing an aging warehouse into a modern, high-tech food...

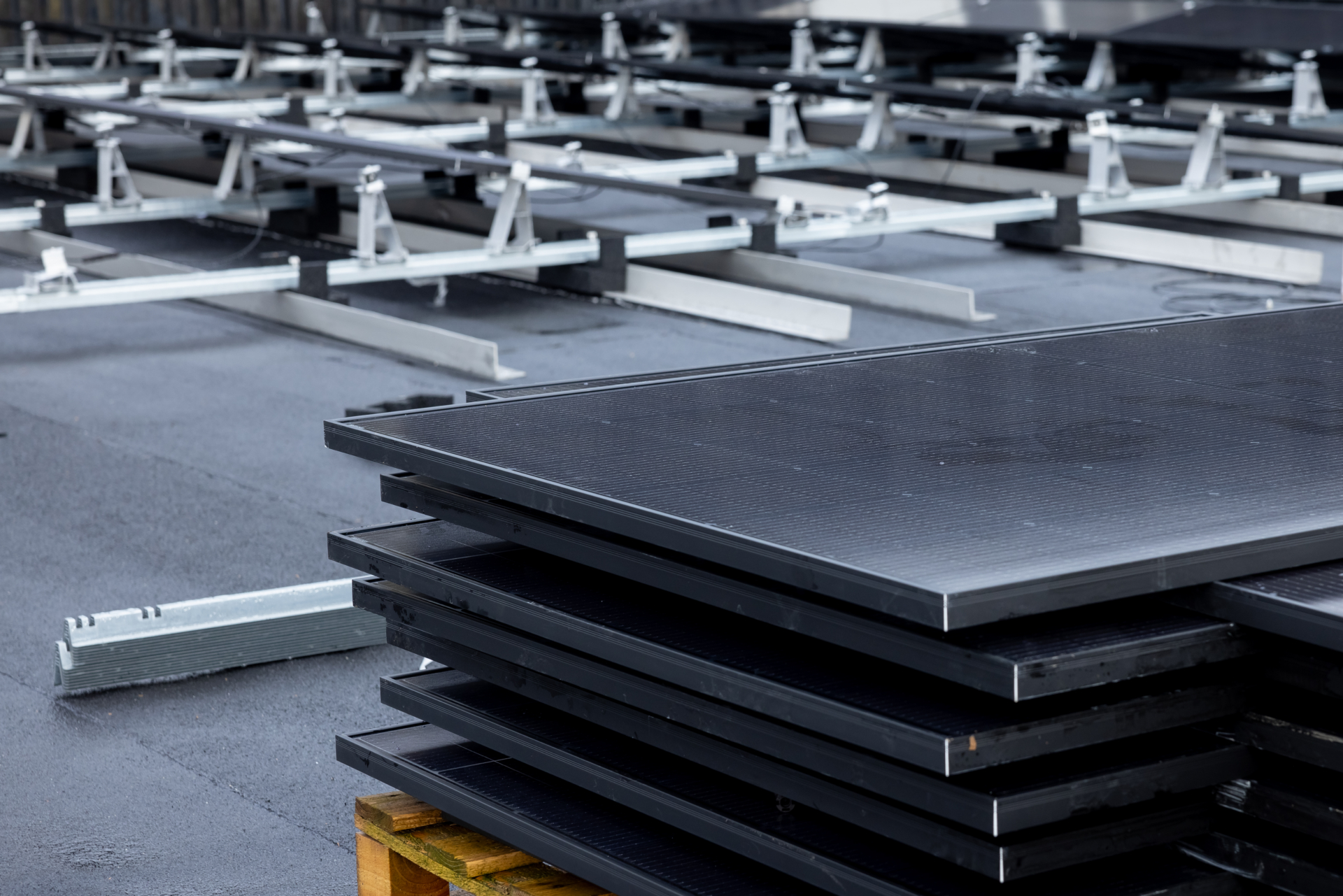

Ambrey Baker was contracted to reinforce the roof structure at GXO’s Peterborough facility to support the additional weight of a new solar PV system. The...

At Ambrey Baker, we take pride in contributing to the success of esteemed clients, and our recent collaboration with Melton Foods on a comprehensive facilities...